Chucks CENTRO|P - Precision Holder

Greater profitability through unique precision

With CENTRO P we are offering a Precision Collet Chuck, which continues the tradition of our tried and tested Collets in terms of precision and quality. With CENTRO P we are revolutionising Collet Chuck and Collet clamping technology, putting it ahead of the competition in respect of precision, clamping force, flexibility and price-performance.

Don’t waste your money on laborious and costly hydraulic, expansion or shrink fit clamping techniques. Rely on FAHRION instead for your chucks as well the only way to bring the precision of the Collet to your cutting tool.

It’s your choice!

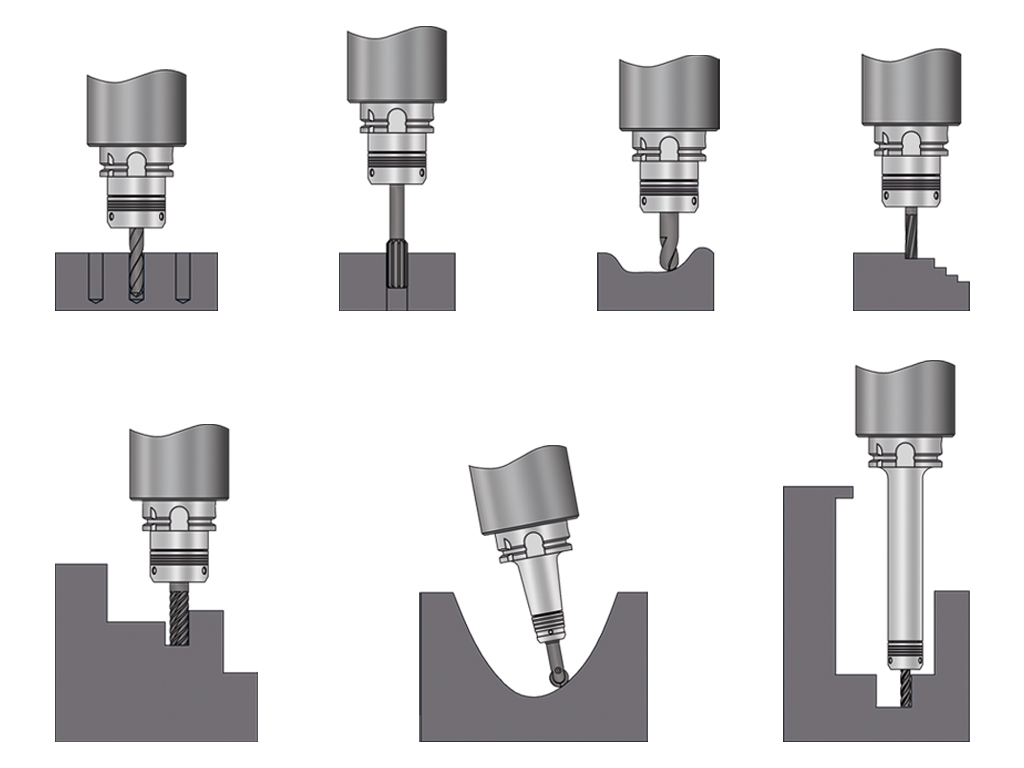

With more than 250 different shaft forms, lengths and diameters we offer a broad range of versions for every possible application. And if we don’t yet have the right chuck for your needs, just contact us. Our philosophy is: ‘if it doesn’t fit, we’ll make it fit!’

CENTRO|P is available in 2 versions:

GERC precision collet chuck for collets complying with DIN ISO 15488-B (ER/ESX) - very high concentricity of ≤ 3 µm with FAHRION GERC-HP collets or ≤ 6 µm with FAHRION GERC-B collets.

GOZ precision collet chuck for collets complying with DIN ISO 10897 (OZ) - extremely stable versions for roughing milling with clamping forces of over 600 Nm with CP432.

*Tap Collets GERC-GB cannot be inserted in GERC precision collet chucks!

Learn more about the properties of the CENTRO|P and the advantages it gives you.

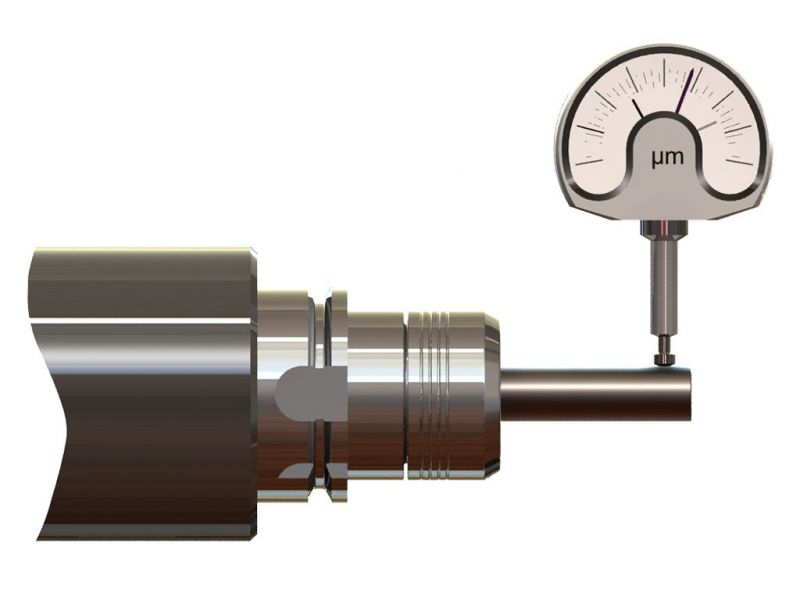

Constant system accuracy with FAHRION GERC-HP Collets ≤ 3 μm*, ≤ 6 μm* with the FAHRION GERC-B Collets.

Vibration

Possible vibration during the application is absorbed by the Collets.

Many different versions are available, adapted to the respective tasks and challenges faced when milling, drilling, threading, etc.

Suitable for dry processes and hard milling up to 200°. Resistant to temperature changes.

Maintenance free

You don’t have to check the clamping force, provided the Collet diameter is the same as the tool shank and you comply with the operating instructions. Full clamping force is maintained, even when in storage for a long time.

Efficiency through precision

Extremely high concentricity and repeatability

- minimises manufacturing tolerances

- reduces rework to a minimum thanks to optimum surface quality

- preserves tools and maximises tool service lives

You save money!

Efficiency through quality and innovation

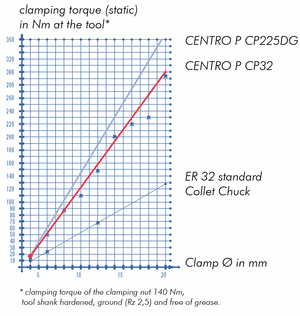

High clamping force and rigidity

- for the transmission of high torques and high radial forces

- prevents wandering of the tool

- decreases the risk of the cutting tool pulling itself out

- reduces imbalance and oscillations

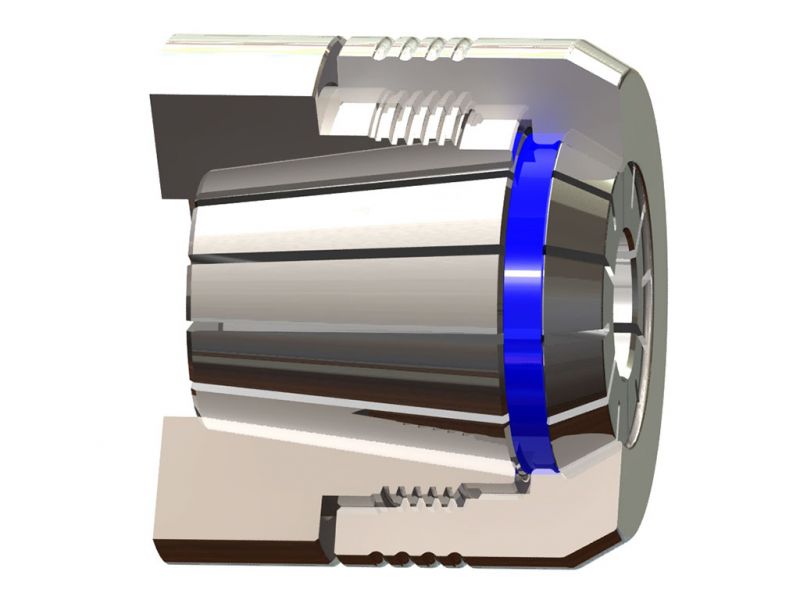

Very good cushioning

- reduces spindle load

- reduces chatter vibration

- maximises tool service lives

Excellent material and machining quality, along with advanced technology

- increase flexibility

- improve clamping force

- increase tool life

- maximise clamping and production safety

- guarantee high availability

- ensures high availability

Get ahead of your competitors!

Cheap doesn’t always mean that you save money and rigid holders without cushioning cost money, because more and more spindle manufacturers record the oscillations/vibrations in the working spindle of the machine tool using a so-called black box and read out these data in the event of warranty claims.

Due to ever increasing cutting speeds, the demands on the maximum possible speed of the machine spindle are also growing. In order to achieve speeds of 20,000 rpm or higher, the spindle manufacturers have to install hybrid bearings (metal-ceramic composite) or even pure ceramic bearings into the machines.

The disadvantage of such bearings is their sensitivity to impacts or knocks – i.e. oscillations of any kind.

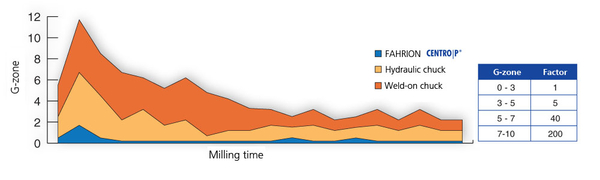

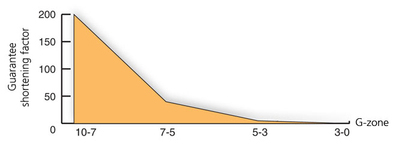

And because these oscillations are not completely avoidable, but shorten the life span of the spindle, they are recorded, grouped into G ranges, converted into hours by means of a factor (depending upon the G range) and subtracted from the actual warranty hours still remaining.

This results in costs: The replacement of the spindle of such a machine costs on average around 25,000 euros.

With a warranty period of 4000 hours, for example, that corresponds to spindle costs of 6.25 euros /hour.

If just one hour is worked in the range 7-10 G, then this hour costs around 1,250 euros at a factor of 200.

Even small oscillations in high G ranges reduce the remaining warranty hours and cost you money!

Example 1:

With 20% of working time in the G-range between 3 and 5 (factor 5) the warranty period reduces to 2,222.22 hours.

Example 2:

With 10% of working time in the G-range between 3 and 5 (factor 5) the warranty period reduces to 2,857.14 hours.

Example 3:

With 5% of working time in the G-range between 3 and 5 (factor 5) the warranty period reduces to 3,333.33 hours.